Introduction to Ribbon Optical Cable

Ribbon Optical Cable has been around for decades, however, the use case for it is becoming more widely accepted and adopted. As we see the demands of bandwidth double the need of fiber, ribbon cable becomes the simplest, easiest, and fastest way to plan for future network needs.

What is Ribbon Fiber Optic Cable?

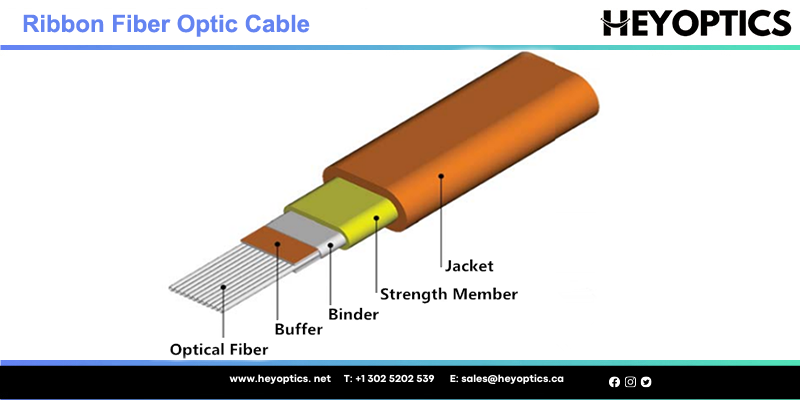

Ribbon optical cable is a type of cable widely deployed in campus, building and data center backbone applications where high fiber counts are required. There are 8 fibers, 12 fibers, 24 fibers and other higher fiber counts available on the market. At present the 12-fiber ribbons are readily accessible and identifiable with ribbon identification numbers and TIA-598 compliant fiber color coding, which make it prevalent in today’s networks. Usually there are two kinds of outer jacket of ribbon optical cables: non-flame-retardant and formulated flame-retardant. The former is often used in outside plant applications, while the latter is typically used for indoor applications. Here is an example of ribbon optical cable construction.

Features and Benefits of Ribbon Fiber Cable

The first advantage of a ribbon fiber jumper is the ability to save time and reduce installation costs. Since the cables are pre-banded (usually made up of 12 sets of separate fibers), installers and technicians can perform simpler, faster mass fusion stitching so that all fibers in the ribbon matrix can be stitched together at the same time. This means less installation time, lower installation labor costs, and faster recovery during downtime.

The second benefit of the ribbon fiber cable is increasing the fiber density in a given cable. Of particular importance is fiber density, as fiber counts increase in the data center, it is an attractive feature and benefit.

Disadvantages of Ribbon Fiber Optic Cable

Traditional fiber optic cables can bend smoothly in all directions-within the appropriate bending radius specification, the motion plane of the ribbon fiber is limited, but can only bend along its longitudinal axis. This is called “priority bending “-Because the cable only likes to bend along a moving shaft. There is no control over the direction of the ribbon structure inside the cable, so any bending of the ribbon fiber may be perpendicular to its longitudinal banded axis, which may cause stress on the fibers. This can damage the cable and cause insertion loss (signal power loss).

Ribbon Fiber Applications

Ribbon fiber optic cable can be used in indoor FTTH network and indoor/outdoor point-to-point applications, but also for the interconnection and cross-application of MTP fiber wiring box; The 12-core ribbon fiber cable is one of the most widely used ribbon fiber cables, and the 12-core banded fiber jumper can be easily used by LC connectors or SC connectors, such as single-work, Duplex connector or MTP Connector for termination; Ribbon fiber jumper can also be stitched with loose casing cable. The specific approach is to remove the coating of the ribbon fiber jumper and stitch together 12 fiber fuses in batches.

However, ribbon fiber is not always the best choice indoors: when the indoor ribbon fiber is transmitted to the Cabinet, it becomes challenging to operate the cable for termination. In fact, some people say that many ribbon cables feel like “iron bars ” When they are processed. As you can imagine, this makes installation difficult. Even if the termination process is faster, time is likely to be saved due to the complexity of routing these cables to cabinets and racks when the cable is installed for too long.

The Splicing of Ribbon Fiber Optic Cable

Ribbon fiber provides definite size and weight saving, which required the connector, strippers, cleavers, and fusion splicers to be tailored to the ribbon fiber. Below is the simple steps of ribbon fusion splicing:

Ribbon fusion splicer is also called mass fusion splicers, it can splice the entire cable ribbons at on time. Ribbon splicers look similar to single fiber splicers and work in much the same way, except the ribbons are treated as one assembly, stripped, cleaved and spliced by special tools while held in a special holder. The holder is inserted in a special stripper that uses heat to make stripping easier. After stripping, the holder is placed in a special cleaver that will leave all 12 fibers at once. Then the fixture with all the cleaved fibers is placed in the splicing machine. When the second ribbon is prepared, the unit is set for automated splicing.

Conclusion

The ribbon cable is lighter, more compact and easier to handle and splice. It is best suited for future expansion since the transmission protocols progress to higher and higher data rates. Ribbon cable is now easily obtained using traditional simplex or duplex connectors as well as MTP Connectors, which make them suitable for various applications.