What are the packaging and welding processes of TOSA and ROSA optical devices?

In the period of 5G optical communication, 25G/100G TOSA/ROSA gadgets pursue exceptionally high reliability, and the laser soldering procedure of Heyoptics Laser is the critical warranty for device product packaging.

ICC News Presently, optical fiber interaction has actually concerned the 5G era, and 5G has greater as well as higher requirements for optical devices, such as little size, high combination, broadband, and also low power intake. The device rates consist of 25G, 50G, 100G, 200G as well as 400G optical tools, of which 25G and 100G optical gadgets are one of the most commonly made use of 5G communication tools, and also the handling and also application of laser soldering innovation is fully grown.

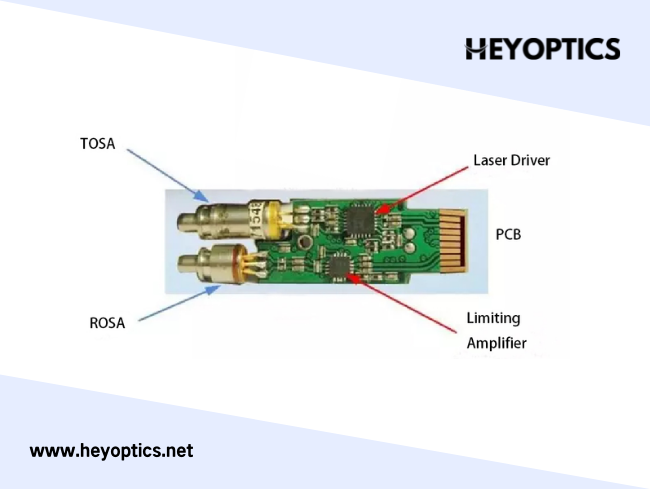

TOSA, ROSA, and also electronic chips are the three parts with the highest possible cost percentage in optical modules, accounting for 35%, 23% and also 18% specifically. The technological barriers in TOSA, as well as ROSA, generally depend on two elements: optical chips and packaging technology. The following is an introduction to the optical gadget product packaging process by Heyoptics Laser:

Generally, ROSAs are packaged with optical splitters, photodiodes (change light stress with voltage) and trans-impedance amplifiers (amplify voltage signals), and TOSAs are packaged with laser chauffeurs, lasers and also multiplexers.

The packaging processes of TOSA and ROSA mainly consist of the following:

TO-CAN coaxial package;

Butterfly bundle;

COB (ChipOnBoard) package;

BOX package.

TO-CAN coaxial bundle: The covering is generally round, due to its little dimension, it is challenging to integrate into cooling, it is hard to dissipate warmth, and it is challenging to make use of for high power result under high existing, so it isn't easy to use for long-distance transmission. Presently, the main usage is still in 2.5 Gbit/s and also 10Gbit/s short-distance transmission. But the price is low and the procedure is basic.

Butterfly plan: The covering is generally a cuboid, and also the framework, as well as execution functions, are generally complicated. It can have built-in fridges, heat sinks, ceramic base blocks, chips, thermistors, backlight monitoring, as well as can support the bonding cables of all the above parts. The shell location is huge, the heat dissipation is great, and it can be utilized for numerous rates and also 80km long-distance transmission.

COB product packaging is chip-on-board packaging. The laser chip complies with the PCB substratum, which can achieve miniaturization, light weight, high reliability and also affordable. The typical single-channel 10Gb/s or 25Gb/s rate optical module takes on SFP bundle to weld the electric chip and also the TO packaged optical transceiver elements to the PCB board to develop an optical component. For a 100Gb/s optical module, when utilizing a 25Gb/s chip, 4 sets of components are required. If an SFP plan is used, it will certainly call for four times the room. COB product packaging can incorporate TIA/LA chip, laser array and also receiver selection right into a little area for miniaturization. The technological trouble lies in the placing precision of the optical chip patch (influencing the combining optical result) as well as the cable bonding quality (affecting the top signal quality, bit mistake price).

Package bundle is a butterfly package as well as is used for multi-channel identical packaging.

Optical components with rates of 25G and also below mainly use single-channel TO or butterfly bundles, with common production procedures and automation equipment, as well as reduced technical barriers. However, for high-speed optical modules with a price of 40G as well as above, it is restricted by the price of the laser (mostly 25G), which is primarily recognized by multi-channel parallelization. As an example, 40G is recognized by 4 * 10G, and 100G is understood by 4 * 25G. The packaging of high-speed optical components puts forward higher needs for parallel optical style, high-speed electromagnetic interference, volume decrease, as well as warmth dissipation under raised power consumption. As the rate of optical modules is getting greater as well as higher, the baud rate of a solitary channel is currently facing a bottleneck. In the future, to 400G and 800G, the identical optical design will certainly come to be more and more essential.