Ribbon Optical Cable vs Loose Tube Optical Cable: What's the Difference?

The ribbon cable has been around for decades, however, the use case for it is becoming more widely accepted and adopted. As we see the demands for bandwidth double the need of fiber, ribbon cable becomes the simplest, easiest, and fastest way to plan for future network needs.

Ribbon cables offer higher fiber counts and greater fiber density than any other cable construction designed for the outside plant (OSP), four times the highest-fiber-count loose tube cable. Ribbon cables also enable mass-fusion splicing, whereby each 12-fiber ribbon can be spliced in a single, straightforward procedure. This facilitates fast network installation and restoration after cable cuts.

So, in an OSP deployment, should you choose ribbon or traditional loose tube cables? Which is more economical? That's what we're going to discuss today.

What is Ribbon Optical Cable?

Ribbon fiber optic cable is a typical fiber optic cable. Unlike beam optical cable, ribbon fiber optic cable is arranged into a strip. Ribbon fiber optic cable is a convenient solution for space and weight problems. The cable ribbons are actually coated optical fibers placed side by side, encapsulated in Mylar tape, similar to a miniature version of wire ribbons used in computer wiring. A single ribbon may contain 4, 8 or 12 optical fibers. Their ribbons can be stacked up to 22 high.

Application of Ribbon Optical Cable

Ribbon optical cables can be used in indoor FTTH networks and indoor/outdoor point-to-point applications, as well as interconnection and crossover applications of MTP optical fiber distribution boxes;

The 12-core ribbon fiber optic cable is the most widely used type of ribbon fiber optic cables. The 12-core ribbon fiber optic cable can be easily terminated through simplex, duplex connectors such as LC connectors or SC connectors or MTP connectors;

Ribbon optical cables can also be spliced with loose tube optical cables. The specific method is to remove the coating of the ribbon optical cable and splice together 12 optical fibers in batches.

What is Loose Tube Optical Cable?

Loose tube optical cables are widely used for outside plant trunks because they offer exceptional and reliable protection for the fibers under high pulling tensions and can be easily protected from moisture with water-blocking gel or tapes. It typically consists of multiple buffer tubes that contain one to 12 fibers and are stranded around a central member. Contingent upon the deployment location, a non-flame or flame-retardant jacket is applied.

Comparison Between Ribbon Optical Cable and Loose Tube Optical Cable

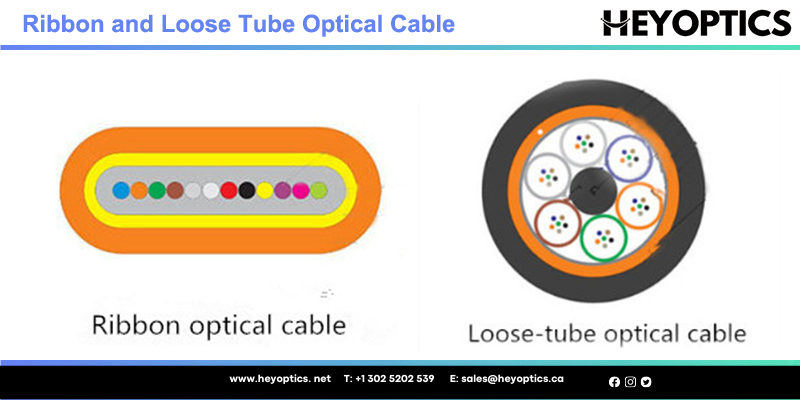

Both ribbon optical cables and loose tube optical cables are staples of the telecommunications industry. Both products perform well in harsh outdoor environments, and both are available in a multitude of configurations. However, the major differences between them lie in the manner in which the individual fibers themselves are packaged and managed within the cable. A ribbon optical cable has the individual fibers precisely bonded together, the number of which ranging from 4 to 24 fibers. Typically, they are bonded together in a group of 12 and placed inside a tube that holds multiple ribbons. In contrast, a loose tube optical cable design has between 2 to 24 individual fibers housed in multiple buffer tubes with each fiber detached from the other.

As we all know, ribbon optical cables and loose tube optical cables perform well in harsh outdoor environments, and can provide a variety of insulation, armor and other configurations. Compared with loose tube optical cables, ribbon optical cables not only The tube fiber optic cable has the same performance and is superior in terms of fiber density. In addition, ribbon cables require shorter splicing time than loose tube cables, which means that ribbon cables require less installation costs and emergency recovery time.

Advantages of Ribbon Optical Cable

In some cases, it is better to adopt ribbon optical cable when the fiber counts hold a key issue. Since mass fusion splicing technology is enabled by ribbon optical cable, it can be spliced much more rapidly than loose tube cables. This advantage allows for less installation time, less installation labor cost, and significantly less emergency restoration time. Besides, It enables a smaller footprint in splice closures and telecommunications room fiber management. Ribbon optical cables offer greater packing density in higher fiber counts which enable more efficient use of limited duct space. And it is typically very cost competitive in counts above 96 fibers.

Advantages of Loose Tube Optical Cable

However, some applications such as fiber-to-the-home, require multiple cable access locations where we pull out only two to eight fibers from a cable for splicing using mid-sheath access techniques. In those instances, ribbon might be less practical for some carriers than conventional loose tube. There are still a few areas where either ribbon or loose-tube is the preferred option. For example, it takes four splices to repair a 48 fiber count ribbon cable compared to 48 splices for the loose-tube equivalent.

Conclusion

Ribbon optical cables can provide the highest optical fiber packaging density, and can also maximize the deployment of optical fibers in a limited space, improve space utilization, simplify fiber termination, save time and money, and are indoor FTTH and outdoor point-to-point applications The ideal solution.

To conclude, there is not a single cable that fits all network designs perfectly and thoroughly. But it is essential to know the options and where they fit best, which may contribute to decrease installation time, labor cost, and emergency restoration time. Before choosing the optimum solution for the specific scenario, just remember to take cable costs, splicing costs and labor hours into consideration.