Do you really know Fiber Optic Patch Panel?

Fiber optic cable has been increasingly applied to meet the need of high speed network. In data centers, the cabling infrastructure turns to be more complicated. Under that situation, keeping good cable management is necessary since messy cabling will cause fiber optic loss and not easy for troubleshooting. Then fiber optic patch panels can serve as the tools for cabling systems.

How to Find the Right Solution for Your Project?

Fiber optic communications has been a rapidly expanding industry for the last 20 years. In its early years, it was mainly used for backhaul communications between large ISP’s. But now fiber is widely used and can be found almost anywhere. It’s probably in your office, on the telephone poles outside your home, and maybe even in your home. With the growth of the fiber industry, a wide array of fiber optic patch panels have been developed to fit the many needs of these varying environments.

If you already know what your project requires, check out our complete Fiber Patch Panel selection.

What is a Fiber Optic Patch Panel?

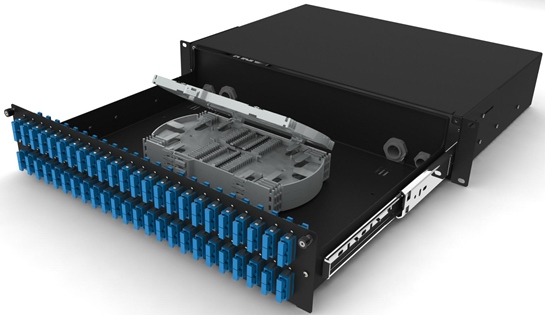

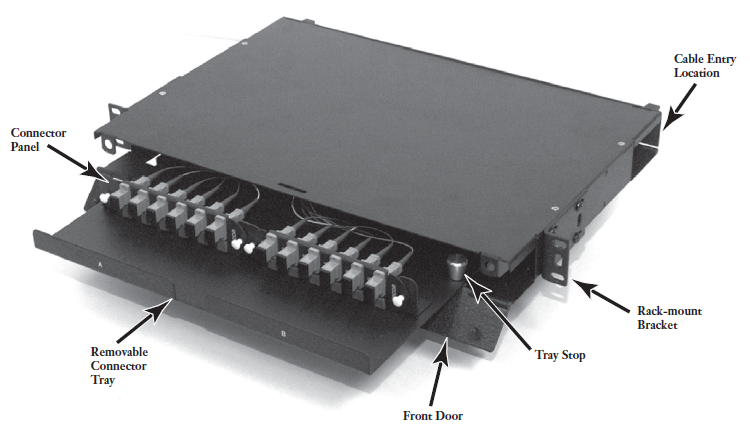

A fiber optic patch panel is commonly described as the interface panel that connects multiple optical fiber cables and optical equipment. Patch panels are rack-mountable onto 19”, 21”and 23” rack systems, and some are designed to be wall-mountable.

In physical terms, it is usually a metal enclosure that houses adapter panels, fiber splicing trays and space for excess fiber storage. Its basic construction consists of an array of ports where each port interfaces with another patch cable which is connected with optical equipment located elsewhere in the building. The adaptor panel provides an interface for both outside and inside ports to the enclosure. The inside ports are fixed as the cables are not meant to be disconnected at any point, whereas the outside ports are for fiber patching cables that can be plugged and unplugged for connections as required.

The splicing trays are neatly embedded in the enclosure to provide fusion with fiber optics pigtails which in turn plug into the fixed inside adapter ports of the adapter panel.

Fiber Patch Panel Structure

A typical fiber patch panel contains four parts: enclosed chamber (rack mount or wall mount), adapter panels, connector adapters (providing low optical loss connection through mating appropriate connectors) and splice tray (organizing and securing splice modules). Adapters on a fiber patch panel are available in different shapes, such as LC, SC, MTP, etc. Most times, all adapters are of the same type in a panel. But sometimes a panel with different types of adapters is needed when more than one type of fiber optic connectors used in a network.

Fiber patch panel has two compartments. One contains the bulkhead receptacles or adapters, and the other is used for splice tray and excess fiber storage. Patch cable management trays are optional for some patch panels and make possible the neat storage of excessive patch cable lengths.

The benefits of using a fiber patch panel

Facilitates the easy termination of fiber optic cables

Well-organized and easy-to-manage connections of all the input jacks/ports into a patch panel in a central location

Provides an easier means to connect different devices in different orders as all of the changes can be made at the patch panel

Avoids cost incurred through wear and tear on the input ports of networking equipment as all the connections are patched using the ports in the patch panels

Common patch panel specifications

Indoor or outdoor

Rack-mountable or wall-mountable

Front access only or both front and rear access

Direct patching only or splice and patch

Unloaded as a bare chassis, loaded with adapters only or loaded with adapters and pigtails

Fixed, sliding or pivoting

Intended application; single fiber, standard ribbon or SpiderWeb Ribbon® (SWR) cable

Fiber count

Rack unit height

Type of adapter required

AFL Hyperscale patch panels offer an innovative and effective solution to meet your fiber optic connectivity needs. A versatile and comprehensive range of fixed, sliding and pivoting patch panels are available to support a variety of applications, installations and capacities.

Stackable, individually rack-mountable or wall-mountable options

1U, 2U, 3U, 4U, 6U & 9U and many more rack unit height options

Patch & Splice, Splice only & Patch only options

All popular connector styles supported

Comprehensive range of capacities and footprints

LGX-compatible options

Compatible with pre-terminated cables

Comprehensive installation guides provided

Installation accessories provided and additional accessories available for purchase

Fiber Patch Panel Ports

Fiber patch panel ports provide a place for data to enter and exit the panel. The number of these ports vary from 12, 24, 48, 64, 72, 96 to 288 and even more. Actually there is no limit to the number of ports on a patch panel. As long as there is enough room, you can fill the enclosure without interfering with the integrity.

Fiber Termination in the Patch Panel

In a patch panel, pigtail or field termination can be used for the connection. If it uses the pigtail approach, a splice tray is needed in the patch panel. This method provide the best quality connection and is usually the quickest. The second method uses fiber optic connector for field termination. A fiber optic connector is directly installed onto the individual fibers. This method usually takes longer time than pigtail but doesn’t need a splice tray in the patch panel. However, the connection quality may not be as good as pre-terminated pigtails.

Summary

Fiber patch panels are very useful especially in the high density data center. They feature with the benefits of easy fiber installation, maximum flexibility and manageability. Although patch panels are attractive, it’s the best only when it fits your application. No matter rack mount or wall mount type, loaded or unloaded, you should better choose the most suitable one based on your own situation.