Cable Tie Is Not as Easy as You Think

When think of cable ties, most people would firstly thought of a bunch of self-locking throwaway plastic strips. One might think a cable tie is just a cable tie. You can frequently find racks, frames or panels in the cabling system. They are necessary components for cable management. However, sometimes you may easily forget about a small but helpful tool for cable management — that is cable tie. People’s first impression about cable tie is always a self-locking and colorful plastic strip. They think cables ties are pretty much the same. Seldom have they considered about whether they are choosing the right cable ties or not.There are many uses for cable ties. And there are also a wide variety of cable ties which are designed for different applications. The plastic self-locking cable ties are the most commonly used ones. However, even these simple plastic loops come into various types according to their color, length, width, and serrations. Proper cable ties do not only provide long-life and dependable services but also better cable management, especially in data centers and server rooms which are the worlds of various cables. To choose the right cable tie for your applications, this post would like to offer some suggestions when making your decisions.

Cable ties have to be able to meet the most varied demands these days as they are used in the widest range of operations — from the simple bundling of cables with cable ties to the absolutely specific use of cable ties under extreme conditions. Thus, many factors are taken into consideration during the design of cable ties.

Locking Design of Cable Tie.

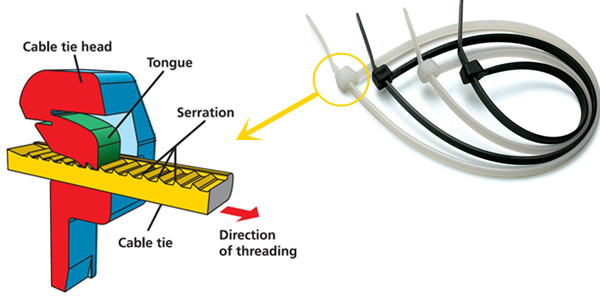

Self Locking Cable Tie: The most important thing of a cable tie is its locking technology. With a good locking design, cable tie can provide firm locking for the cables. The most commonly used cable tie is also called zip tie, which is one-piece design with a lot of serration on the cable tie to lock the cables firmly. The following picture shows the structure of this cable tie. This design allows the cable tie to perform to the published minimum tensile strength.

Locking Design of Cable Tie

Self Locking Cable Tie: The most important thing of a cable tie is its locking technology. With a good locking design, cable tie can provide firm locking for the cables. The most commonly used cable tie is also called zip tie, which is one-piece design with a lot of serration on the cable tie to lock the cables firmly. The following picture shows the structure of this cable tie. This design allows the cable tie to perform to the published minimum tensile strength.

Magic Velcro Cable Tie: This type of cable tie is also reusable. The hooks and hairs on the cable tie can provide firm locking for the cables (shown in the following pictures). And it can make cable management safer and more convenient. It is also widely used in household applications to organize wires. This Velcro cable tie is usually sold in rolls.

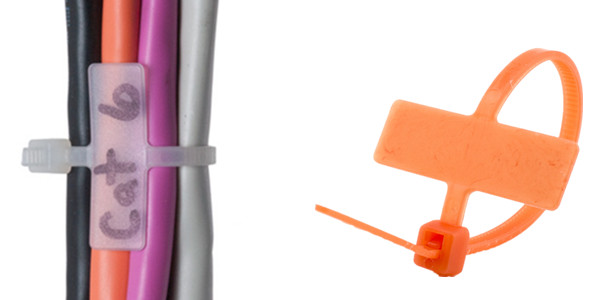

Identification Cable Tie: the above mention cable ties are all available in different colors. Color is a useful feature for identification. Thus, customers can use cable tie in different colors for identification. However, it happens that the color is not enough for cable identification if there are too many cables or too much information. Then, an improved cable tie with a marker or label attached on the cable tie is offered (shown in the following picture).

Materials of Cable Tie

The function and performance are also largely depended on the materials of the cable ties. The above mentioned cable type are the most commonly used ones, which are usually made of plastic, Nylon and Velcro. However, for some harsh environment, elements like temperature and strength should be considered during cable tie selection. There is a type of cable tie which is made of stainless steel, usually known as heavy duty stainless steel cable tie(as shown in the following picture). It is commonly used in outdoor applications.

Construction

Cable ties can be classified as either one-piece or two-piece construction. One-piece cable ties typically have a plastic locking device molded into the head of the tie. The locking device ratchets the notched strap to tighten and lock. This design has a lower cost of manufacturing and is used for general applications around home or office. Compared to one-piece cable ties, two-piece cable ties are with higher performance. They consist of a stainless-steel locking device embedded into the head of the tie, and a smooth locking strap. This design offers high tensile strength, and resistance to mechanical and environmental stress for applications that require greater performance than what a general cable tie offers. In addition, the smooth, infinitely adjustable strap also allows for the exact bundled tightness. The head of the two-piece cable tie engages the strap when installed, and permanently locks in place. With a lower profile and smoother cross-section, the uniform cross-section distributes stress across the strap more evenly than with one-piece cable ties. Thus, the two-piece cable ties are more resistant to brittleness and breakage in harsh environments, particularly appropriate for harsh conditions, such as ultraviolet exposure, extreme temperature, and exposure to moisture or chemicals, as well as for applications where retrofitting is not an option.

Material

The material design of different cable ties also needs to consider for different applications, such as occurring indoors or outdoors; the environment’s temperature range; the presence of moisture, chemicals and radiation; flammability issues; and cost. Cable ties are available in a wide range of materials, each with its own specific properties. Among them, the most common type is nylon cable ties. Nylon ties can offer good resistance to weather and ultraviolet rays in lower temperatures. In addition, for applications in harsher environments that require extra durability in the face of heat, chemicals and other corrosive elements, there are stainless-steel cable ties.

Color

The most commonly used cable ties are white and black. But colorful cable ties are also popular with users. These cable ties with rainbow colors are very useful when you are trying to color-code your cables, or just want to match the ties to your equipment. Moreover, you can use different cable ties to mark different cables bunch which is convenient for cable management.

Size

When using cable ties, you should also consider the size and shape. First, be sure to measure the diameter of the cable bundle you’ll be tying and decide the length. In general, to buy cable ties with a little longer length is better. Because no one wants to find out at the last minute that the cable ties are too short to use. In addition to length, width or shape are also important considerations to choose optimal cable ties for your cable bunch.

Special Features

Though the standard-design cable ties can meet most of our requirements, sometimes, we still need something special for special applications. For instance, most cable ties lock permanently, but sometimes, we would prefer to looking for a solution that cable ties can be undone without actual cutting. Then, releasable cable ties have been launched in the market. In a releasable cable tie, the built-in locking tab can actually be disengaged, allowing the tail end of the tie to be pulled free from the head. Releasable cable ties tend to cost a little more than the standard type, but they save money and are more eco-friendly in the long run because you can reuse them over and over instead of just throwing them away. Additionally, for different special applications, there are mounted head cable ties, marker ties, etc.

Other Factors to Consider During Cable Tie Selection

The length of cable ties available in market ranges from 4 to 52 inches. The cable tie length should be longer than the diameter of the cable bundle. It cannot be too long or too short. The proper width of a cable tie will also help a lot. Both the length and width of the cable ties should be depended on the applications.

Other Factors to Consider During Cable Tie Selection

The length of cable ties available in market ranges from 4 to 52 inches. The cable tie length should be longer than the diameter of the cable bundle. It cannot be too long or too short. The proper width of a cable tie will also help a lot. Both the length and width of the cable ties should be depended on the applications.

Conclusion

It is very unprofessional to use random cable ties for your cable management. Knowing the secrets about cable ties can lead you to choose the matching cable ties for your applications. This will greatly reduce the unnecessary problems during actual practice. Actually, no matter cable ties or other assembles, each component of cabling system should not be underestimated. The right selection will greatly increase the efficiency of a cabling system.