UPC or APC — Which One to Choose?

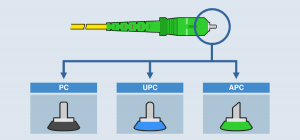

When it comes to fiber optic cables, you might be curious about the description that contains UPC or APC. For example, what is LC UPC to LC UPC? And what is SC APC to SC APC? UPC and APC are actually two polish types of fiber ferrules. This article will help you explore the world of UPC and APC to know which one is the better solution for your network.

1. What is PC?

PC is physical contact. It is the most common grinding method of optical fiber connector on optical fiber jumper, which is widely used in the equipment of telecom operators. Although the end face of the optical fiber connector looks flat, it is actually slightly bent and polished, and the highest point of bending is the center of the fiber core, which can effectively reduce the air gap between optical fiber components. In general, the return loss of fiber jumper with PC grinding mode is - 40dB.

What is the Meaning of UPC and APC?

Whenever a connector is installed on the end of fiber, loss is incurred. Some of this light loss is reflected directly back down the fiber towards the light source that generated it. These back reflections will damage the laser light sources and also disrupt the transmitted signal. To reduce back reflections, we can polish connector ferrules to different finishes.

There are four types of connector ferrule polishing style in all. UPC and APC are two types of them. UPC stands for Ultra Physical Contact connector. The current trend is using it in deadlines to allow operators to perform networks tests for example by using an OTDR. APC stands for Angled Physical Contact connector. APC is the most used polishing type nowadays.

What is APC & UPC?

Return loss is inevitable when installing a connector on the end of fiber. It is a back reflection generated by the light source. However, severe light loss will damage the laser light sources and disrupt transmitted signals. Therefore, different polish connector ferrules are made to avoid serious return loss. UPC and APC are two widely used polish types. Here are some specific information about UPC and APC.

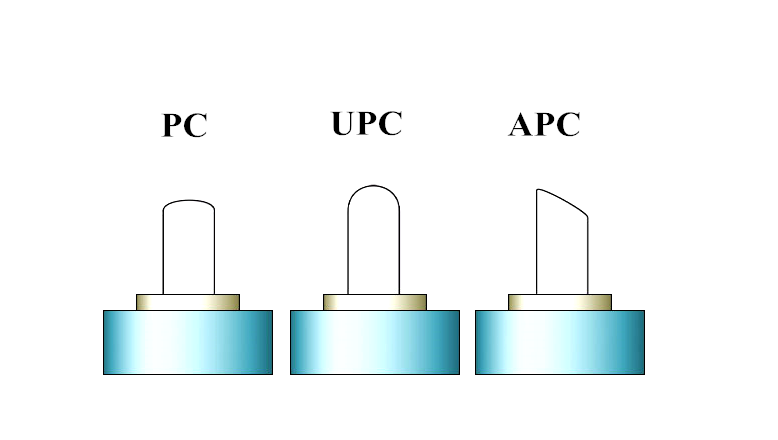

UPC, namely ultra physical contact, is evolved from PC with a better surface finish. UPC connector relies on machine polishing to deliver its low optical return loss characteristics. Its rounded finish created during the polishing process allows fibers to touch on a high point near the fiber core where light travels. In addition, when using the UPC connector, make sure your laser’s specifications can handle the return loss your UPC connector will generate.

APC, namely angled physical contact, is very different from UPC. The end face of APC connector is precisely polished at an 8-degree angle to the fiber cladding so that most return loss is reflected into the cladding where it cannot interfere with the transmitted signal or damage the laser source. But it is extremely difficult to field terminate an APC connector at 8 degrees with any consistent level of success. Therefore, if an APC connector is damaged in the field, it should be replaced with a factory terminated APC connector.

How to Distinguish UPC from APC?

Many differences can be found between UPC and APC connectors:

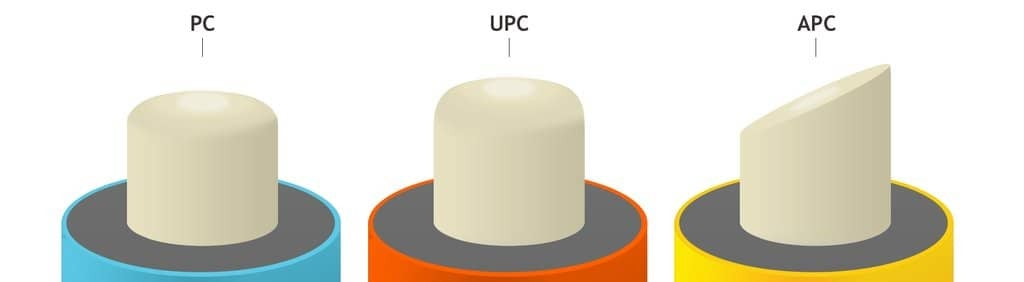

Point one, end faces. As we have discussed before, UPC connectors are polished with no angle, but APC connectors is polished at an 8-degree angle.

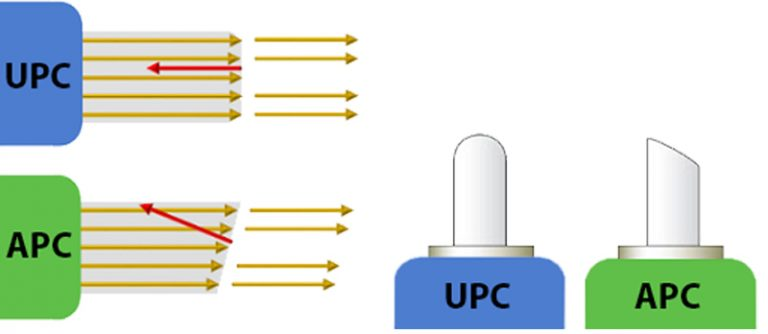

Point two, ways of light reflection. Their different polish end faces directly lead to their differences in ways of light reflection. Any reflected light is reflected straight back towards the light source if an UPC connector is used. But the APC connector causes reflected light to reflect at an angle into the cladding instead of straight back toward the source.

Point three, return loss. Since their light reflection patterns are varied, their levels of return loss are also different. APC connector offers lower return loss of -65 dB than UPC of -50 dB. As a matter of fact, connectors can achieve better matching performance if return loss is lower.

Point four, connector color. This is the most obvious difference that can be seen from the surface. UPC connector usually has a blue body while APC connector has a green body.

Insertion Loss

Different polishing styles determine the quality of optical fiber, which results in different performances regarding the connector’s insertion loss and return loss. Insertion loss refers to the signal loss caused by the connector or cable. In general, the typical insertion loss of PC, UPC, and APC connectors should be less than 0.3dB. Compared with APC connectors, UPC connectors are usually easier to achieve low insertion loss due to the smaller air gap.

Return Loss

Return loss, also known as reflection loss, is a parameter representing the signal reflection performance. The end faces of APC connectors are beveled, so the return loss of APC connectors is usually better than UPC connectors. In general, the return loss of the PC fiber cable is -40dB. UPC return loss is higher relative to PC, generally at -55dB (or even higher). APC industry-standard return loss is -65dB.

Application

APC is more suited for high bandwidth applications and long distance links, such as FTTx, passive optical network (PON) and wavelength division multiplex (WDM), they are more sensitive to return loss. If the return loss requirement is not high, UPC is a better choice.

Eight Degrees of Separation

The main difference between APC and UPC connectors is the fiber endface. APC connectors feature a fiber endface that is polished at an eight-degree angle; UPC connectors are polished with no angle. UPC connectors are not exactly flat, however; they have a slight curvature for better core alignment. Another more obvious difference is color. UPC connectors are blue while APC connectors are green.

UPC-vs-APC-reflection

What does this difference mean in terms of performance? With UPC connectors, any reflected light is reflected straight back toward the light source. The angled endface of the APC connector causes reflected light to reflect at an angle into the cladding vs. straight back toward the source. This causes some differences in return loss, which is a measurement of reflected light that is expressed as a negative dB value (the higher the value, the better). Industry standards recommend that UPC connector return loss should be -50 dB or greater, while APC connector return loss should be -60 dB or greater.

UPC-APC

Remember, return loss is different than insertion loss, which refers to the amount of optical power lost through a connector or cable length. Insertion loss is what we use to determine loss budgets. Achieving low insertion loss is typically easier with UPC connectors due to less air gaps than APC connectors; however, manufacturing techniques have improved significantly to create more precise angles on APC connectors and bring insertion loss closer to that of UPC connectors.

In fact, insertion loss on Belden’s FiberExpress connectors is the same for UPC and ACP singlemode connectors. Our FiberExpress Fusion Splice-On Connectors exceed standards when it comes to insertion loss.

Application Considerations

Some applications are more sensitive to return loss than others; they call for APC connectors. For example, in higher optical wavelength ranges (above 1500 nanometers) like those used for RF video signals, reflected light can adversely impact the signal. That is why we see APC connectors being used by most cable companies and other FTTX providers in outside plant applications.

APC connectors are also commonly used in passive optical applications (both GPONs and passive optical LANs) due to the fact that many of these systems also use RF signals to deliver video. Future higher-speed passive optical networks and other WDM applications that will use higher wavelengths via singlemode fiber will also likely require the reduced return loss of APC connectors.

One thing that should be noted is that APC and UPC connectors cannot and should not be mated. Not only does mating cause poor performance because the fiber cores will not touch, but it can also destroy both connectors. The last thing you want to do is cause permanent transmitter damage—especially with higher-cost singlemode equipment.

Another important point: Cable loss is typically the smallest contributor to system attenuation. The largest loss comes from the connector. Higher-performing connectors offer dB savings that are more significant, measurable and consistent.

Which One to Choose?

If you are still confused about which polish type to choose, the best way is to see whether their applications complies to yours. In general, the APC type has a better performance than the UPC type. APC is best for high bandwidth applications and long haul links. For example, FTTx (fiber to the x), passive optical network (PON) and wavelength-division multiplexing (WDM) that are more sensitive to return loss, thus APC is a better solution to offer the lowest return loss. However, massive employment of APC connectors will cause higher cost. In this way, UPC might be a better choice because cost budget is of equal importance.

Conclusion

UPC and APC are taken into consideration when choosing fiber optic patch cables. Both of them can reduce light loss and protect laser sources from damage.Conclusion

It is improper to say whether PC, UPC or APC is the best polish type of fiber connectors. When choosing fiber connectors for specific applications, factors such as cost and operability should be considered. However, there is one rule that should be followed: for those applications which high precision optical fiber signaling matters, choose APC; for less sensitive digital systems, PC or UPC is capable.A wise selection should be based on your actual condition.