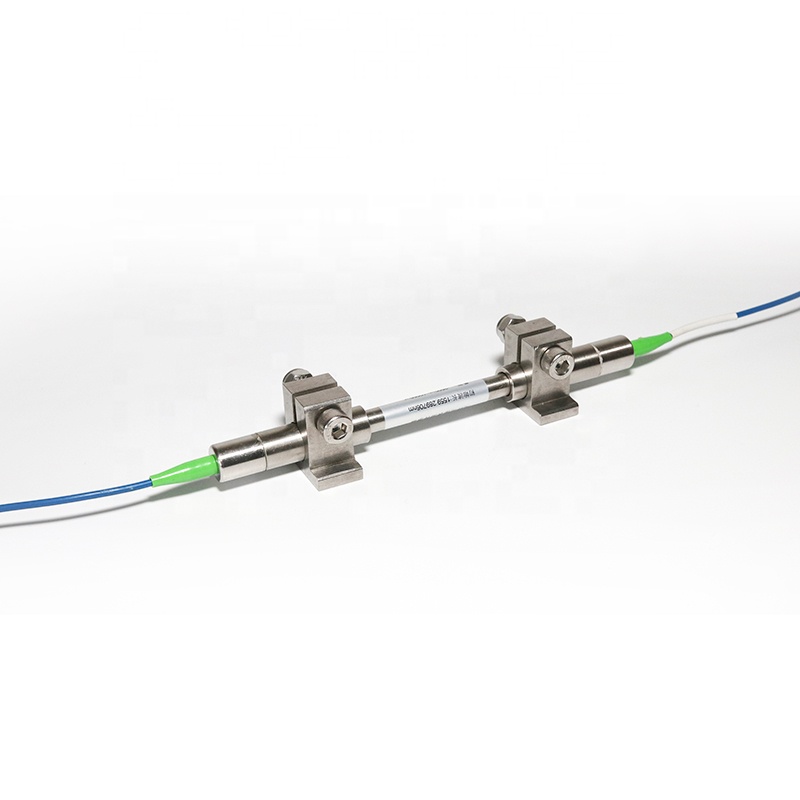

The strain sensors make use of the sensitivity of fiber grating to measure the strain. The FBG is fixed inside a stainless steel housing between two anchoring points. The housing consists of a sliding mechanism that allows both ends to move freely relative to each other.

Features:

Excellent repeatability and reliability

Excellent waterproof performance

Try harsh environments

Applications:

The strain sensors used in civil engineering construction monitoring and long-term health monitoring, such as: bridges, interchanges, high-rise buildings, large steel construction.

Specifications

| Parameter | Unit | Minimum value | Typical value | Maximum value | Remark |

| Center Wavelength | nm | 1510 | / | 1590 | Customized |

| -3dB bandwidth | nm | / | 0.25 | / | Customized |

| Accuracy | 1‰ | ||||

| Strain Measurement Range | με | -1500 | / | 1500 | |

| Temperature Range | ℃ | -40 | / | 80 | |

| Insertion loss(IL) | dB | / | 0.5* | / | |

| Dimension | mm | φ12 * 102 | weldable FBG | ||

| 78(L) * 14(W) * 7(H) | Surface Mounted FBG Strain Gauge | ||||

| φ33 * 110 | Embedded FBG Strain Gauge | ||||

| Pigtail Type | mm | Amoured Or Jumper Cable | |||

| Connector | FC/APC | ||||

| Option: with temperature compensation | |||||

| (i.e. built-in 2 fbg inside, one for strain measurement, another for temperature compensation) | |||||